ELASER-300-10-A

POA

Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have

Demonstrations: To book your demo please click below.

Book Your DemonstrationCategories:

Free Delivery

For orders over £75

Interest Free Finance

Up to 10 months

Payment Secured

Safe shopping with us

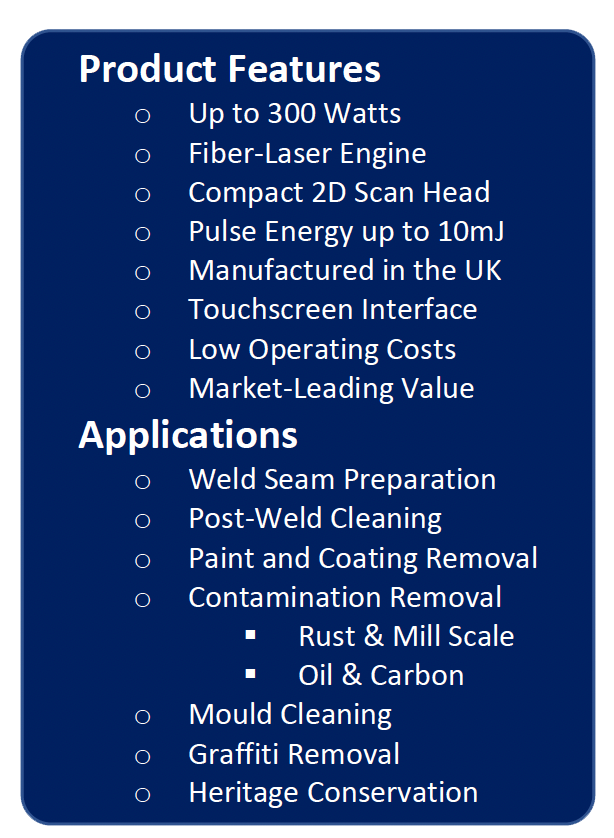

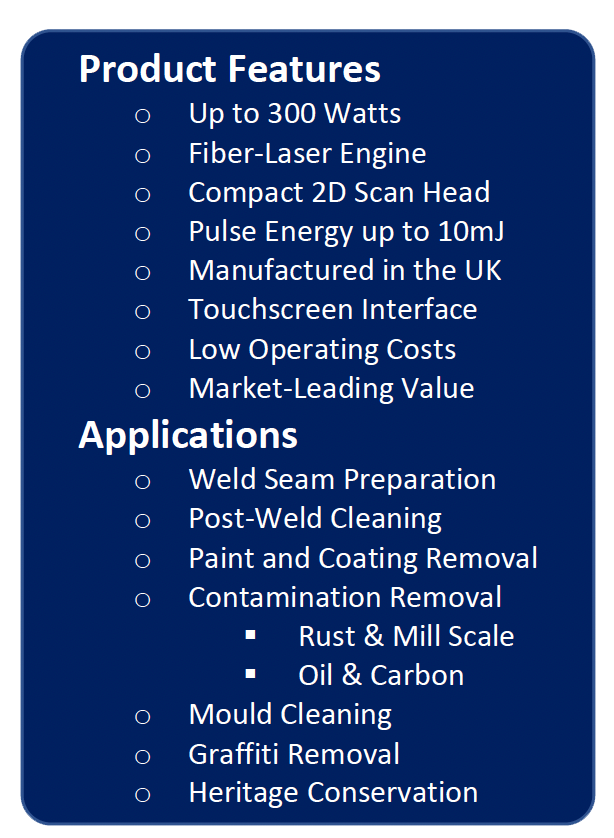

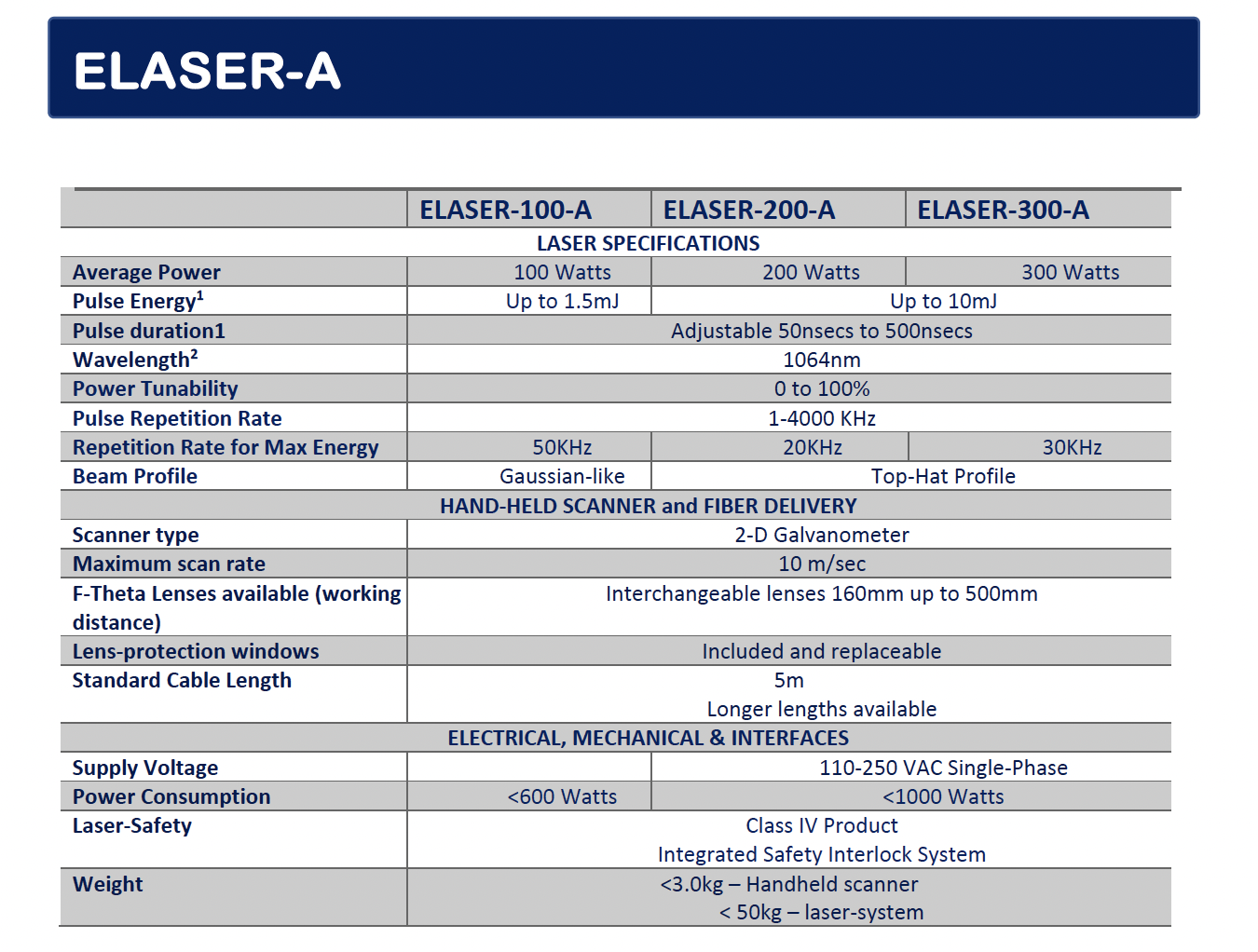

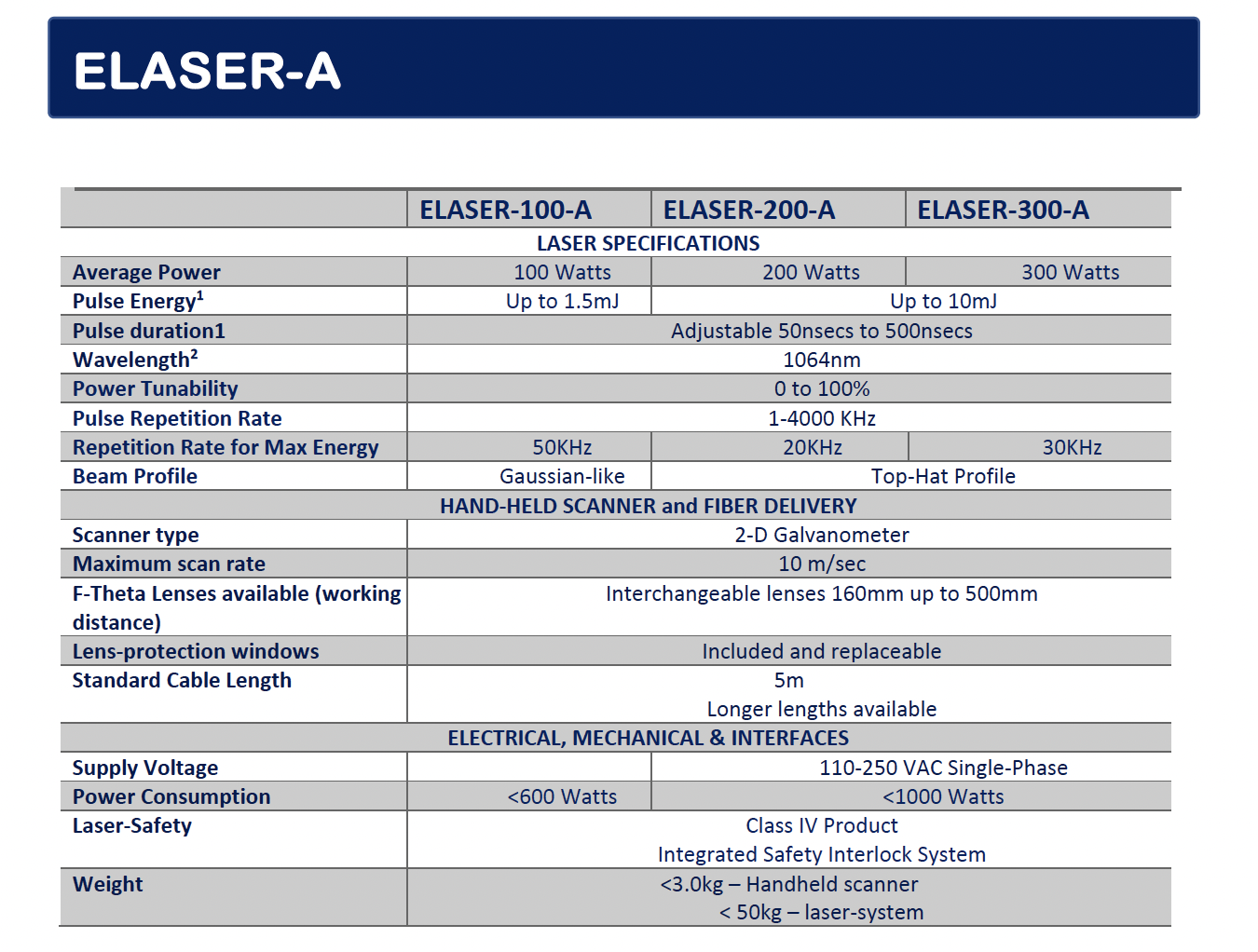

- Single Phase

- 300 Watts

- 10mj Pulse Energy (Max)

- Top Hat Beam Profile

- Designed and built in the UK

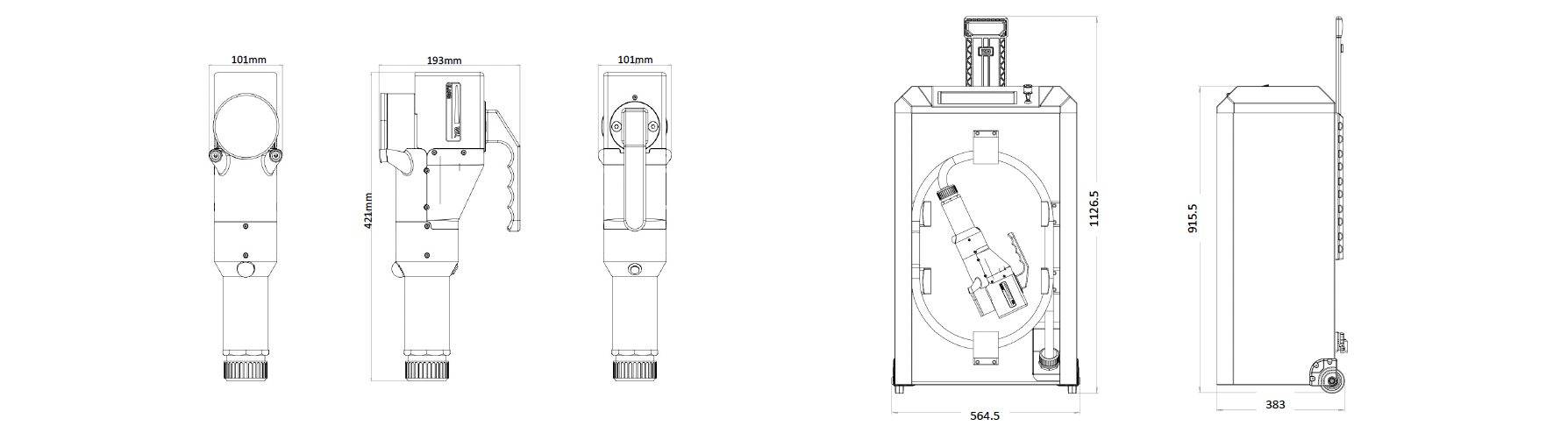

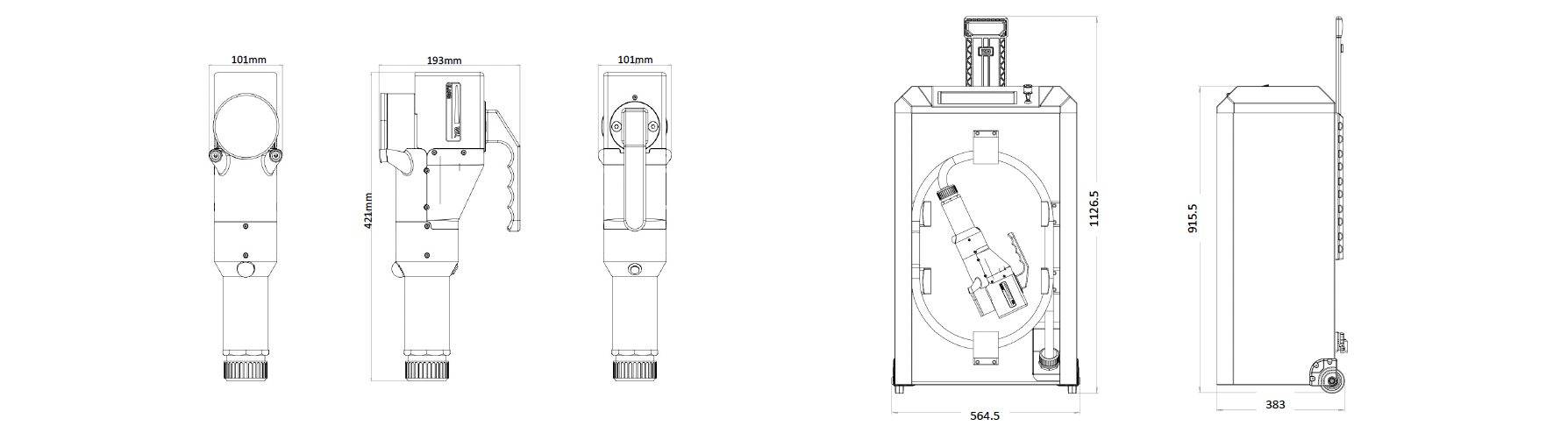

- Extremely Portable

- 2 Year Warranty (Conditions apply)

ELASER-300-10-A

Laser-cleaning eliminates the need for consumables in surface cleaning processes. Unlike traditional media-blasting, water-jetting and chemical cleaning methods, no water, chemicals or abrasives are required. Laser cleaning generates minimal waste, no mess and the underlying surface is unaffected by the process.

ELASER-A, air-cooled portable laser-cleaning systems are unique to the market-place - UK-manufactured, high-quality, performance and reliability, yet priced competitively to drive expansion of laser-cleaning within industrial applications.

Powered by compact, robust fiber lasers and incorporating a portable, lightweight 2D laser scanner and intuitive user interface, ELASER will adapt to optimise any surface-cleaning, surface-preparation or coating-removal application.

ELASER technology will drive down your operating costs, extend lifetime of equipment and parts and enable maximised uptime within manufacturing.

What Do I Need to Know About Laser Welding and Cleaning?

Laser welding and cleaning are sophisticated, high-precision technologies that deliver exceptional results in various applications. However, these technologies come with inherent risks that must be carefully managed to ensure the safety of operators and surrounding personnel. The primary hazards associated with laser operations include exposure to laser radiation, intense heat, and harmful fumes, which can result in serious injuries, such as eye damage, burns, and respiratory issues. To minimise these risks, it is essential to implement strict safety protocols and use the appropriate protective equipment.

Key Safety Measures:

- Protective Equipment: Always wear certified laser helmets, goggles, and other protective eyewear specifically designed for the wavelength and power of the laser being used. Inadequate eye protection can lead to permanent eye damage. To find the correct protective gear, please visit Laser Helmets and Eye Protection.

- Laser Enclosures: Laser welding and cleaning operations should be conducted in controlled environments, such as laser enclosures or cabins. These enclosures provide essential protection by containing laser beams and ensuring the safety of both operators and others nearby. For more information, see Laser Welding Enclosures.

- Laser Safety Advice: It is crucial for everyone involved in laser operations to undergo comprehensive laser safety training. This training covers potential risks and outlines safety measures to prevent accidents. For expert laser safety advice, refer to Laser Safety Advice.

- Laser Awareness Training: All personnel should be familiar with the fundamentals of laser safety by enrolling in Laser Awareness Training. This course covers important topics, including the physics of lasers, potential hazards, and appropriate safety protocols.

- Laser Safety Officer Training: For organisations using high-powered lasers (Class 3B, 3R, or 4 lasers), appointing a Laser Safety Officer is mandatory. This role ensures that laser equipment is operated safely. Laser Safety Officer Training provides the knowledge and skills required to manage laser safety effectively.

- Laser Welders and Cleaners: Whether using laser welders for precise welding or laser cleaners for surface preparation, it is vital to follow the manufacturer's guidelines and adhere to established safety standards. For more information, explore Laser Welders and Equipment and Laser Cleaners.

Conclusion:

By strictly adhering to proper safety protocols and using the correct protective equipment, the risks associated with laser welding and cleaning can be greatly reduced. Always ensure that both you and the work environment are adequately protected to handle the demands of laser operations.

For further safety information and resources, please visit the recommended links above. Prioritising safety in all laser-related tasks is essential to maintaining a secure working environment.

| monthly | From As Little As £944.47 Plus VAT per month over 60 Months Call our team on 01952 582 260 for your quotation |

|---|---|

| GYS Offer | No |

| Is Laser Product | Yes |

| Electrical Input Voltage | 230V |

| Short Description |

|

| POA | Yes |

Check your eligibility

Check your eligibility