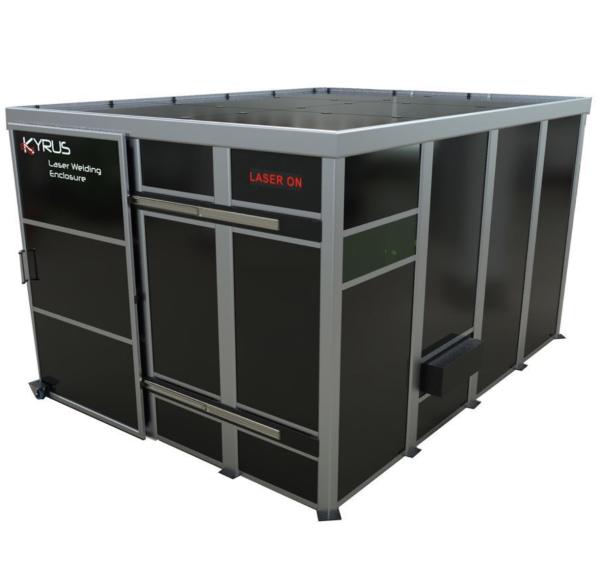

Laser Enclosure c/w 1.3m Sliding Door 3m x 3m Class 4

POA

Call our sales team on 01952 582 260 to discuss pricing, product availability & any questions you may have

Demonstrations: To book your demo please click below.

Book Your DemonstrationCategories:

Free Delivery

For orders over £75

Interest Free Finance

Up to 10 months

Payment Secured

Safe shopping with us

Tailored for the latest generation of handheld laser welders, this enclosure meets IEC 60825-4 standards to ensure maximum safety. It integrates seamlessly with the built-in safety systems of your laser welding equipment, providing a reliable and secure environment for your operations.

With a compact footprint of 3.1m x 2.1m, this enclosure is ideal for processing small fabrications and components. It features a 1.2m wide hinged door equipped with labyrinth flash seals to prevent accidental exposure to laser radiation.

The enclosure boasts fully integrated “plug and play” electronics, including a door interlock, power distribution, cable management, and LED lighting for straightforward setup and operation. Its modular design allows for flexible configuration and future expansion, adapting to your evolving needs.

Delivered as a flat pack for ease of installation, it can be assembled quickly on-site. For added convenience, professional installation services are available. The enclosure also includes floor seals to minimize visible reflections and illuminated laser warning signage to enhance safety awareness.

You have two external viewing options: a CCTV system with a live screen (recommended) or an optical viewing window. Additional features include light-tight service connections, an optional enclosed roof, and customizable extraction options to suit your specific requirements.

3m x 3m Class 4 Laser Enclosure with 1.3m Sliding Door

The Kyrus 3m x 3m Class 4 Laser Enclosure is specifically designed to create a safe and controlled environment for the use of handheld laser welders. This enclosure plays a crucial role in mitigating the risks associated with high-powered laser equipment, ensuring a secure workspace.

The latest generation of handheld laser welders and cleaning systems offers impressive speed, ease of use, and the ability to produce high-quality, consistent welds across a variety of materials and thicknesses. While these technologies significantly enhance productivity, they also necessitate strict safety and personal protection measures. It is vital to maintain safety standards while leveraging these advanced tools.

For those working with Class 4 laser welders, using an appropriate enclosure is essential to reduce potential hazards. Kyrus has developed a standard “plug and play” range of enclosures, meticulously designed to provide the necessary safety for your operations.

This 3m x 3m enclosure comes with a 1.3m sliding door, which is designed for smooth operation and space efficiency. The sliding door not only provides easy access but also helps maintain the integrity of the enclosure’s safety features, including protection against accidental laser radiation exposure.

In addition to its robust safety features, this enclosure is highly practical. Its modular design allows for flexible setup and future expansion, making it adaptable to changing operational needs. The enclosure is supplied as a flat pack for straightforward assembly, with professional installation services available if desired.

Key features include fully integrated “plug and play” electronics such as door interlocks, power distribution, cable management, and LED lighting, ensuring seamless integration with your existing laser welding equipment. The enclosure also includes floor seals to prevent visible reflections and illuminated laser warning signage to enhance safety.

For monitoring purposes, the enclosure offers two external viewing options: a recommended CCTV system with a live feed or an optical viewing window. It also includes light-tight service connections, an optional enclosed roof, and customizable extraction options to meet your specific requirements.

The Kyrus Laser Welding Enclosure is more than just a safety precaution—it’s a vital component of any operation utilizing Class 4 laser welders, ensuring a balance between productivity, efficiency, and protection.

Key Safety Measures:

- Protective Equipment: Always wear certified laser helmets, goggles, and other eye protection designed for the specific wavelength and power of the laser being used. Inadequate eye protection can lead to permanent eye damage. Visit Laser Helmets and Eye Protection for the right protective gear.

- Laser Enclosures: Conduct laser welding and cleaning operations in controlled environments such as laser enclosures or cabins. These provide essential protection by containing laser beams and ensuring a safe working space. For more information, see Laser Welding Enclosures.

- Laser Safety Advice: It is crucial for all personnel involved in laser operations to undergo comprehensive laser safety training. This includes understanding the risks and implementing safety measures to prevent accidents. For expert laser safety advice, refer to Laser Safety Advice.

- Laser Awareness Training: Ensure that all personnel are familiar with the basic principles of laser safety by enrolling in Laser Awareness Training. This training covers key topics including the physics of lasers, potential hazards, and safety measures. For more details, visit Laser Awareness Training.

- Laser Safety Officer Training: For organisations using high-powered lasers (Class 3B, 3R, or 4 lasers), it is mandatory to appoint a Laser Safety Officer. This role is critical in ensuring the safe operation of laser equipment. The Laser Safety Officer Training will equip individuals with the knowledge and responsibilities needed to manage laser safety effectively. Learn more about this training at Laser Safety Officer Training.

- Laser Welders and Cleaners: Whether you are using laser welders for precision joining or laser cleaners for effective surface preparation, ensure that your equipment is used in accordance with the manufacturer's guidelines and safety standards. Visit Laser Welders and Equipment and Laser Cleaners for more information.

Conclusion:

By adhering to proper safety protocols and using the appropriate equipment, you can minimise the risks associated with laser welding and cleaning. Always ensure that you are adequately protected and that the work environment is fully equipped to handle the demands of laser operations.

For further safety information, visit the recommended links above, and always prioritise safety in your laser-related tasks.

| GYS Offer | No |

|---|---|

| Lead Time | Call To Discuss Lead Time & Availability |

| Is Laser Product | Yes |

| Short Description | Tailored for the latest generation of handheld laser welders, this enclosure meets IEC 60825-4 standards to ensure maximum safety. It integrates seamlessly with the built-in safety systems of your laser welding equipment, providing a reliable and secure environment for your operations. With a compact footprint of 3.1m x 2.1m, this enclosure is ideal for processing small fabrications and components. It features a 1.2m wide hinged door equipped with labyrinth flash seals to prevent accidental exposure to laser radiation. The enclosure boasts fully integrated “plug and play” electronics, including a door interlock, power distribution, cable management, and LED lighting for straightforward setup and operation. Its modular design allows for flexible configuration and future expansion, adapting to your evolving needs. Delivered as a flat pack for ease of installation, it can be assembled quickly on-site. For added convenience, professional installation services are available. The enclosure also includes floor seals to minimize visible reflections and illuminated laser warning signage to enhance safety awareness. You have two external viewing options: a CCTV system with a live screen (recommended) or an optical viewing window. Additional features include light-tight service connections, an optional enclosed roof, and customizable extraction options to suit your specific requirements. |

| POA | Yes |

Check your eligibility

Check your eligibility