Plasma Cutters

Plasma cutters for industrial and DIY use

Metal cutting is amongst the most used processes in the manufacturing and fabrication industry today.

Plasma cutters use the 4th state of matter, plasma, to cut through metals such as steel and aluminium. They can cut through practically all conductive materials. Plasma cutters send an electronic arc through gas (usually compressed air). This then transforms into a plasma arc which is used to cut through the metal.

Plasma cutters produce a large amount of profiled parts in the UK. Rather than utilising hand held plasma cutting machines, computer controlled machines are utilised to cut steel and other thin and thick materials. Thick steel plate (15MM+) can be cut with outstanding precision. When a high quality plasma cutting machine is utilised tolerances can be within +/- 0.1MM with an impressively clean cut edge.

CNC plasma cutting is a great method of improving productivity for your fabrication business. Why? it is a much faster method than hand cutting. You can also save on business costs by bringing your profiling and part manufacturing in-house.

High speed automated plasma cutting systems are often paired with a plasma cutting table. These systems utilise a jet of hot plasma to cut through materials such as stainless steel and other electrically conductive metals.

Hand held plasma cutters are most commonly used in repair or demolition applications. As this type of machine requires human control the precision is not as high as automated plasma cutting systems. Therefore, this type of machine lend themselves to "rough and ready" applications.

For example, utilising a plasma cutting machine with a large cut capacity and a built-in air compressor, such as the Elettro 57i (pictured below), in a demolition area is an ideal application for a hand held plasma cutter.

The operator can utse the cutting torch to cut through materials such as RSJ's, bolts, nuts etc.. whilst being able to maneuvre and move the lightweight and compact plasma cutting machine.

Welding Supplies Direct are distributors for industry leading plasma cutter brands. These brands include Hypertherm, Oxford and Thermacut, as well as many others. We supply plasma cutters for use in CNC applications along with hand cutting plasma cutting machines with built in compressors.

Choosing a plasma cutter

We advise you to choose a plasma cutter based on 3 criteria:

- Maximum required cut

- Available electrical input

- How often you will use it

If you are planning on using the machine for extended periods of time you will need to ensure the machine has a good duty cycle. This is especially true if you are planning on using the machine on a computer controlled plasma application.

Maximum cut capacity is how thick the material can be for the plasma cutting machine to cut through. Available electrical input supply can either be single phase or three phase; this will determine which machines you can consider purchasing. Three phase machines often have a higher cut capacity.

The user should also consider the availability of plasma torch spares. When selecting a plasma cutter ensure that you can easily purchase nozzles, electrodes, retaining caps and swirl rings. You also need to ensure that there is a wide range of cutting tips (nozzles) available to suit your requirements when cutting thin and thick materials.

CNC plasma cutting machines

We supply a range of CNC plasma cutters for use in automation applications. Our range of CNC plasma tables can be found by clicking here. We also offer Hypertherm Powermax plasma cutters with CPC ports and voltage dividers. These can be found on our Hypertherm Mechanized Plasma Cutters page.

Welding Supplies Direct have vast experience with installing CNC plasma cutters at our customers premises. For example, in 2021 we installed a 4M x 2M Weldplas plasma cutting table for a valued customer in the south of England.

In collaboration with Techserv UK the system was fitted with great success. The new plasma cutter increased our customers productivity levels. It also improved the cut quality when compared with their older CNC plasma cutter.

The Hypertherm MAXPRO 200 power source that we fitted offers huge cut capacities, long consumable life and efficient powering.

This particular plasma cutting system was a HD machine, meaning that the cut tolerance was outstanding.

However, for those who do not require such high accuracy, we also offer the Thermacut GRIDON 1250.

This is a 4ft x 4ft standard definition CNC plasma cutter. When advising our customers we usually pair with one of Thermacut's plasma cutting power sources. This package offers outstanding results at a very competitive price point.

We offer turn-key CNC plasma cutter packages; whatever your requirements are, we can help you find the best match. Call our sales team today chat to one of our friendly advisors. They'll be able to help you find the right plasma cutter!

Plasma Cutter Features

What is pilot arc?

Pilot arc essentially ignite your cutting arc before touching the metal that is to be cut. A high voltage spark ionizes the compressed air in the torch head. This then makes the air conductive and allows the pilot arc to initiate. The pilot arc then flows out of the cutting tip and, once close to the workpiece, will start cutting through the metal.

This allows for zero contact cutting arc initiation.

What is auto set?

Auto-set is similar to synergic parameter setting on a welding machine. Plasma cutters with auto set allow the user to programme the material type and thickness. The machine will then set it's cutting current accordingly. Some machines with auto-set will also advise on a suitable cutting speed.

Utilising a suitable cutting speed allows the users to create a smooth cut, with minimal dross created. When minimal dross is created on a cut the remedial work remains minimal.

What is HF free arc starting?

High frequency arc ignition is a "old hat" style of igniting a plasma cutting arc. Some machines utilise a high frequency and high voltage circuit to initiate the cutting arc. However, this has been slowly phased out due to the issues that can arise when using this arc ignition method.

One particular issue includes the emission of large amounts of radio frequency emissions. This can cause untold issues with electrical products, including televisions and many more.

HF free arc starting completely eliminates the high voltage, high frequency circuit. Thus eliminating the potential harm to electrical items.

What is insufficient air pressure detection?

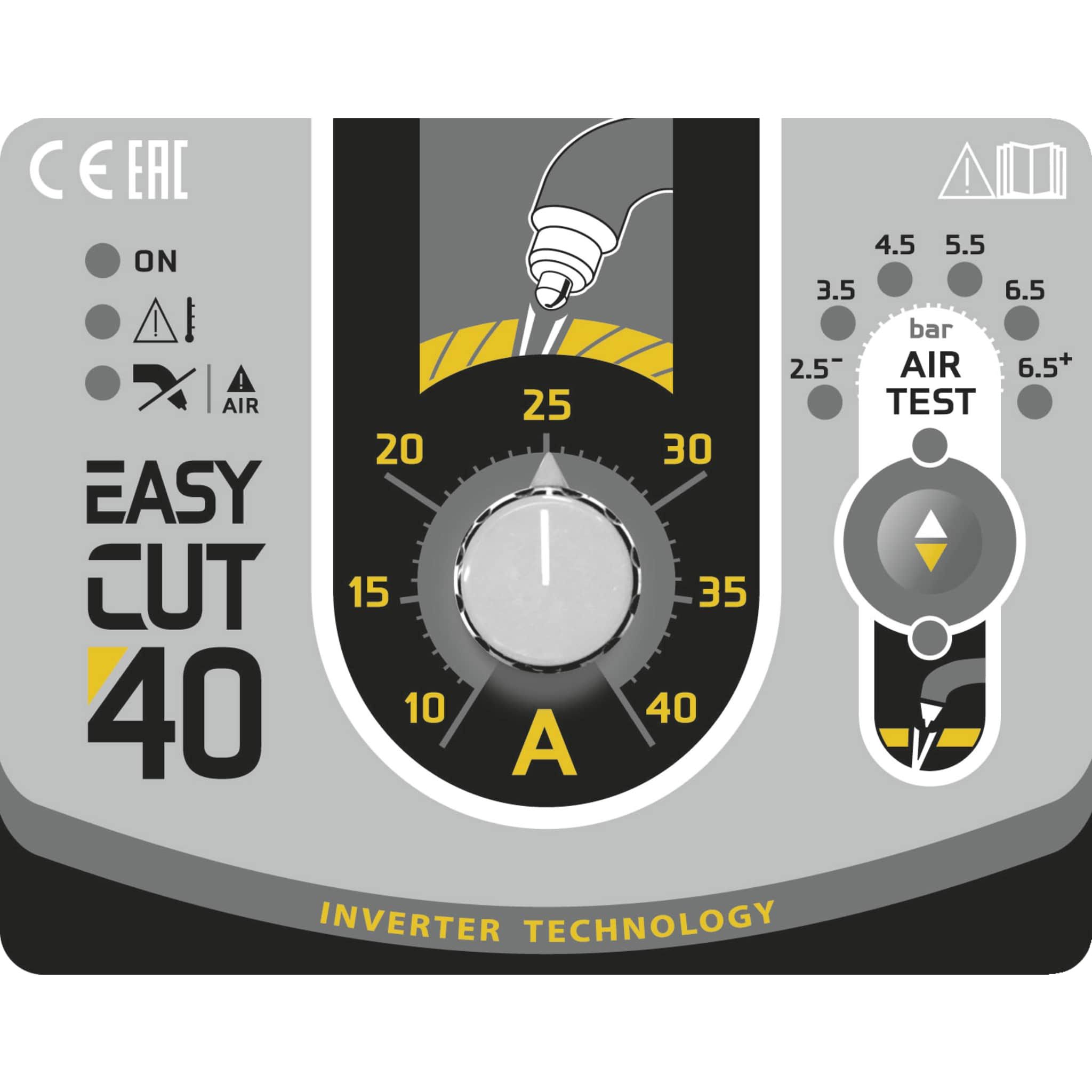

Getting the correct air pressure when plasma cutting is of the utmost importance. Some machines have a built in feature which can detect the incoming air pressure and alert you as to whether the pressure is sufficient.

As can be seen above there is a sequence of LED's which light up to alert you where the incoming pressure is at. The lights will show red if insufficient and green if sufficient.

What is built in air compressor?

Plasma cutting machines require compressed air to work. Oftentimes it is not easy to run a standalone air compressor on-site or in the workshop. Therefore, some plasma cutters have a built in air compressor. An example of a machine like this is the GYS 35KF.

Plasma cutters with a built in air compressor have a permenantly available compressed air supply. The compressor also ensures sufficient air supply is constantly available and supplied.

In addition to this it also limits the input sockets that are required as you do not need to power two seperate machines.